- PSI

-

Pre-Shipment Inspection

Final quality inspection before delivery to ensure the conformity with order requirements and safety.

- DPI

-

During Production Inspection

Confirm the consistency of product and packaging, find defects in advance and track the production schedule.

- IPC

-

Initial Production Check

Assess production progress, verify that raw materials, semi-finished products or finished products meet order requirements.

- FI

-

Full Inspection

Remove all defective products from shipment to ensure the optimal quality!

- CLI

-

Container Loading Inspection

Ensure that the correct goods are shipped in a safe and reliable environment to avoid fraud or trade disputes.

- MA

-

Manufacturing Audit

Check the supplier's legality, scale, trade capacity, production capacity, quality control capacity and so on.

- Softlines

- Machinery

- Consumer goods

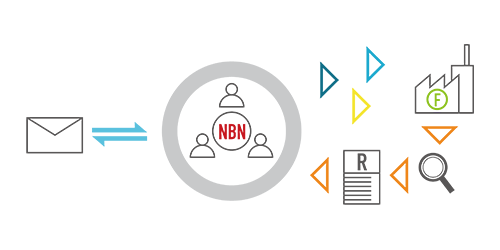

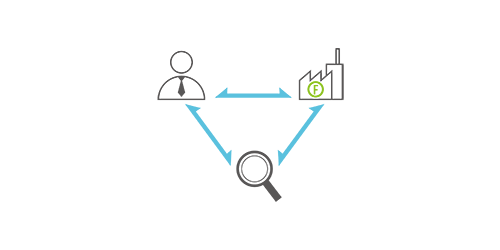

- About NBN

- Over 80 inspectors work for you across China to help you create a controlled supply chain environment--from raw material to finished products and then to shipment.

Submit report within 18 hours after Inspection/Audit

Cancel up to 10 am (China time) the day before

NBN serves more than 10 public interest organizations from around the world.

NBN serves more than 10 public interest organizations from around the world. Our inspectors walked an average of more than 7,500 steps a day.

Our inspectors walked an average of more than 7,500 steps a day. The average cost of travel for our inspectors to visit a factory is usd 14.

The average cost of travel for our inspectors to visit a factory is usd 14. The average inspection time for a man-day is more than 5 hours.

The average inspection time for a man-day is more than 5 hours.